The main purpose of Fuel System Additives for Diesel Engine.

Contamination, corrosion and wear of fuel apparatus elements due to insufficient lubrication can lead to various noticeable disturbances of fuel supply.

The main purpose of the fuel additive is to maintain the nominal characteristics of diesel fuel equipment, protect it from clogging of elements of diesel injectors, plungers, valves. As well as cleaning of fuel equipment and improving fuel characteristics.

What symptoms indicate problems in the diesel fuel system?

Modern diesel engines operate with high fuel pressure in the system.

The injection nozzle can open at a speed of 250 times per second. This makes the engine economical and environmentally friendly, but places high demands on fuel quality. Even a small amount of contamination will cause the fuel supply to malfunction.

Fuel System Additives can help normalize the disturbed fuel system.

But it must be remembered that the best Fuel System Additives must be balanced to have a gentle and gradual effect that does not disrupt the normal processes of the fuel system. That is why you should not expect a quick effect when using quality Fuel System Additives. Time is needed for a mild positive effect.

The best strategy is to use Fuel System Additives as a preventative measure to prevent problems from occurring in advance.

FORCULES.

One of the major problems with the diesel fuel system is that the injectors lose their hydraulic tightness.

A small contamination deforms the needle and a slight wear of the surface is enough for fuel to enter the combustion chamber “chaotically”.

If the nozzle is contaminated, the shape of the fuel plume changes and this leads to incomplete combustion, loss of engine power and smoke from the exhaust pipe.

This is expressed in the fact that when the engine is running, black smoke is seen from the exhaust pipe, and consequently, fuel consumption will increase.

If this happens and the injector is not yet badly damaged, Fuel System Additives can correct this situation with prolonged and continuous use to gradually remove slag and dirt.

It is best to apply Fuel System Additives beforehand. This will clean the needle and its seat, prevent corrosion and significantly reduce the chance of leakage loss.

NOZZLES.

If nozzle operation is impeded by contamination, insufficient fuel may be delivered to the cylinder. Another cause of increased fuel consumption may be improper valve operation due to improper fit.

This disrupts the normal flow of fuel, reduces engine power, and increases fuel consumption. Quality Fuel System Additives will help solve this problem by gradually cleaning the needle and valves of contaminants and improving their fit.

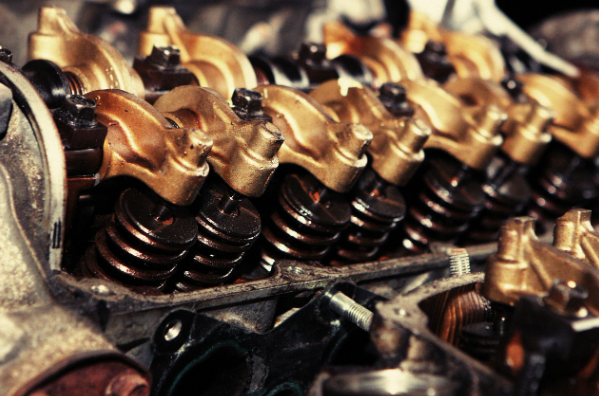

WEAR OF THE PLUNGERS OF THE HIGH-PRESSURE PUMP.

It is the job of the high-pressure fuel pump to create operating pressure in the system. The pressure level is essential for the injectors to deliver the required amount of fuel.

If the pump has to make more revolutions to bring the pressure to the optimum level, the whole process takes longer and occurs later. This leads to a disruption in fuel delivery and the engine loses dynamics and power, and fuel consumption increases.

Quality Fuel System Additives solve the problem with the pump at an early stage, which makes it possible not to repair the plungers of the gasoline pump and not to replace the pump. In the presence of a friction geomodifier (tribotechnical compound) in Fuel System Additives the plunger surface is restored!

PROBLEMS WITH THE FUEL PRESSURE REGULATOR.

A pressure regulator is a valve. Proper operation of the pressure regulator is important as engine operating modes change. A dirty valve does not allow enough fuel through per unit of time.

And when the pressure in the system increases, an excessive amount of fuel enters the cylinders. With incomplete combustion of such fuel, we see black smoke from the exhaust pipe and increased diesel consumption. Unburned fuel shortens the life of particulate filters and catalytic converters, and negatively affects turbocharger performance.

With constant use of Fuel System Additive for Diesel Engine these problems can be successfully solved.

DIFFICULTY STARTING A DIESEL ENGINE.

Difficulty in starting a diesel engine is the most common problem. In such sulchy the starter for a long time, up to 15 seconds cranks the engine, instead of 2-3 seconds.

The reasons for this difficulty may be different. It can be poor compression, poor-quality fuel, crystallization of paraffin deposits at low temperatures, malfunction of glow plugs and so on.

One of the reasons may be contamination of injectors, wear of gasoline pump plungers.

Constant use of high-quality Fuel System Additive for Diesel Engine allows to clean injectors, restore plunger pairs under the action of geomodifiers and exclude fuel system problems from the list of possible causes of difficult starting of a cold engine.

DIESEL ENGINE SMOKE.

Such smoke consists of many tiny particles of unburned fuel. The balance of the fuel mixture of air and fuel is disturbed in this case.

Sometimes it can be a consequence of improper operation of the engine turbine. But most often the problem is in the fuel system. Deposits on the injectors and nozzles lead to the entry of excessive amounts of fuel and its improper and incomplete combustion.

Smoke disturbs the ecology of the surrounding space, leads to systematic low-notice intoxication of passengers and the driver of the car. This can lead to chronic diseases, the cause of which can be determined not immediately.

In addition, as we said earlier, there is a negative impact on the fuel catalyst, particulate filter, turbine blades compressor. Thus, the overall resource of the car begins to decrease with each kilometer. And this is not to mention the increased consumption of diesel fuel.

If this process of operation has not yet led to irreversible consequences, everything can be changed by using Fuel System Additive for Diesel Engine with continuous use for 3-7 thousand kilometers. Approximately this mileage will be sufficient to gently clean valves, injectors and seating surfaces.

The problems of engine power loss, increased fuel consumption, excessive vibration and irregular engine operation can primarily be solved by systematic use of Fuel System Additive for Diesel Engine.

FUEL QUALITY.

Another cause of the problems described above can be poor quality diesel fuel with a low cetane number, which can lead to uneven ignition of the fuel. If the Fuel System Additive for Diesel Engine contains a cetane number correcting compound, it will be a reliable protection against such problems with constant preventive use.

EXCESSIVE VIBRATION.

A separate mention should be made of vibration in the car. Its source is an unevenly running engine.

In some cases, vibration can be a source of breakdowns in various parts and mechanisms of the car due to the resonance effect. This seemingly insignificant problem is being addressed by many research teams around the world.

HOW TO SELECT Fuel System Additive for Diesel Engine.

In an ocean of manufacturers it is not easy to find the pearl of quality. Our manufacturer ranking will help you do just that.

Good luck on the road!